VSimPD Case Study

Magnetron Sputtering is one of several types of Plasma Vapor Deposition (PVD) techniques that is used for laying thin, high-quality, well adhered films onto a surface. Magnetron sputtering is most frequently used for creating industrial coatings, such as those that offer corrosion resistance or anti-reflectivity, or to produce metal layers in microelectronics. By using high powered magnets to trap electrons close to the target surface, magnetron sputtering is an efficient process that can offer higher deposition rates than other PVD techniques.

Although magnetron sputtering was first described in the 1970’s, many companies continue to research the ideal conditions in order to achieve maximum process efficiency. To do this important commercial research, engineers at LG Display Company, Ltd, looked for software that could be used to simulate the large scale plasma sputtering erosion process used in their glass display plate manufacturing. By using simulation software, the team at LG hoped to determine the ideal conditions and design specifications in order to improve efficiency with minimal risk, costs, and testing.

As they looked into a variety of software applications, the LG engineers knew that they needed to use a particle-in-cell code that was capable of self-consistent charged particle simulations with electrostatic, ionization, and particle interactions. Accurately simulating magnetron sputtering is computationally intensive, and they also needed to find a tool that could handle the ion crossing time scales needed for realistic results. After learning about Tech-X’s VORPAL code, which is the engine responsible for VSim simulations, they decided to see if that tool could meet their unique needs.

Using VSim, the LG researchers began to simulate their specific magnetron sputtering process. They measured the absorbed current pattern on the sputter target in their equipment, which is believed to correlate with the target erosion pattern. They then used VSim for the same measurement and saw results that closely matched their sputtering patterns. Since VSim is a parallel computing product that efficiently scales up for challenging problems, they were able to carry their simulations out to ion crossing time scales. After observing that VSim faithfully reproduced their measured sputtering patterns, they integrated VSim into their design process in order to improve their future products.

Using VSim, the LG researchers began to simulate their specific magnetron sputtering process. They measured the absorbed current pattern on the sputter target in their equipment, which is believed to correlate with the target erosion pattern. They then used VSim for the same measurement and saw results that closely matched their sputtering patterns. Since VSim is a parallel computing product that efficiently scales up for challenging problems, they were able to carry their simulations out to ion crossing time scales. After observing that VSim faithfully reproduced their measured sputtering patterns, they integrated VSim into their design process in order to improve their future products.

“VSim was an essential tool for us in our modeling of magnetron sputtering,” said Geejo Lee, manager of Process CI Team, LG Display Co, LTD. “Thanks to the vast array of capabilities available through VSim, including both physics and its parallel computation, we were able to accurately predict the erosion profiles from our current designs and VSim continues to allow us to optimize our designs for the future. The support staff at Tech-X was also extremely helpful during the initial set-up and modeling process.”

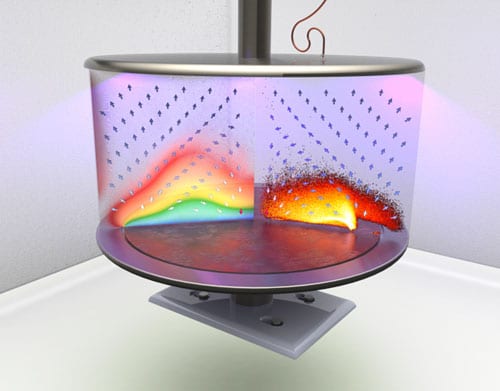

The planar magnetron sputtering system simulated by VSim (top). VSim results showing the spatial distribution of the sputtered copper atoms (bottom). Based on these results, the measured erosion shape of the sputtering pattern is shown (middle right) which closely matches their measured profiles.