Modeling Plasma Wafer Etching

A common use of low-temperature plasmas is in the area known as wafer etching, in which plasma impacts a wafer to etch various microelectronic devices such as memory. One advantage to this method is that the etching is much cleaner and uniform, resulting in better quality control. The ions are the plasma species that do the etching due to their larger mass. We broadly call this application “plasma processing.” In plasma processing, the plasma is generated using capacitively coupled (CCP) or inductively coupled methods (ICP), or a combination of both. In our example, we assume a pre-loaded plasma in the simulation.

Kinetically Model Plasma Species

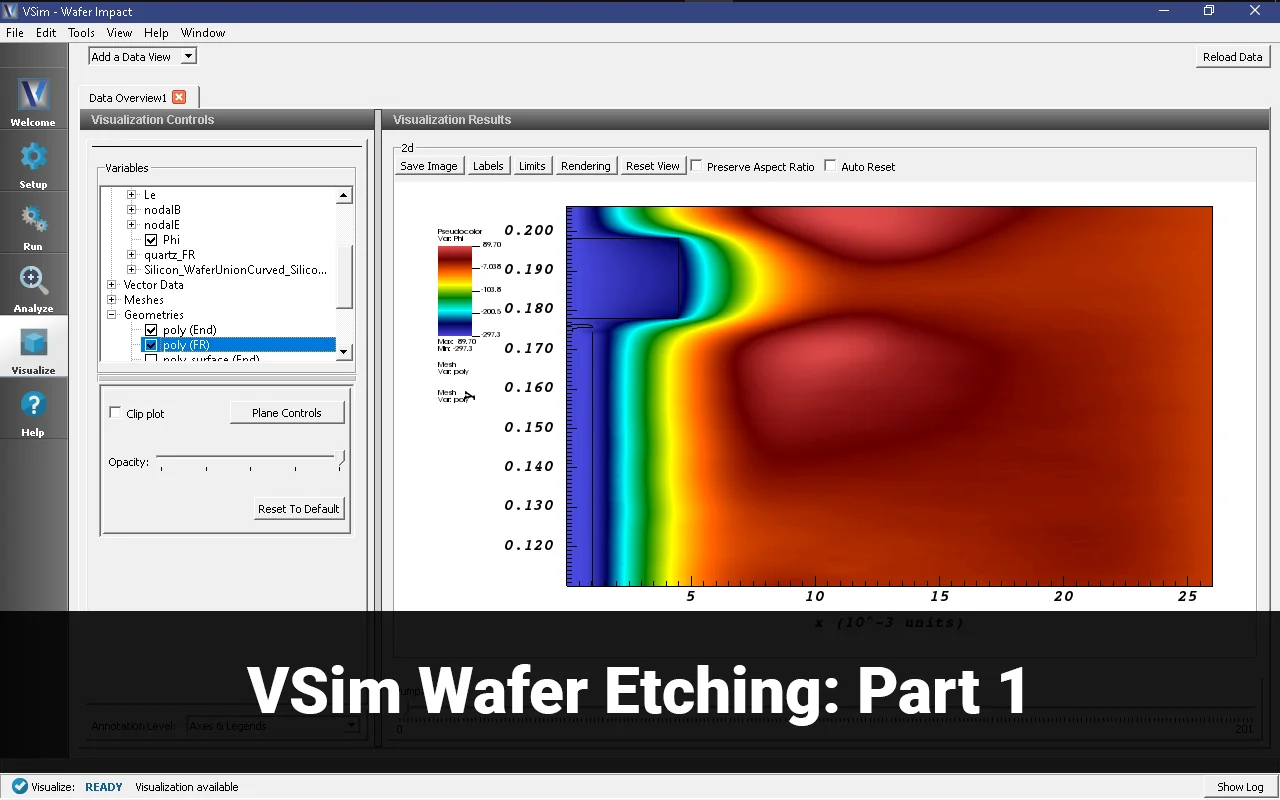

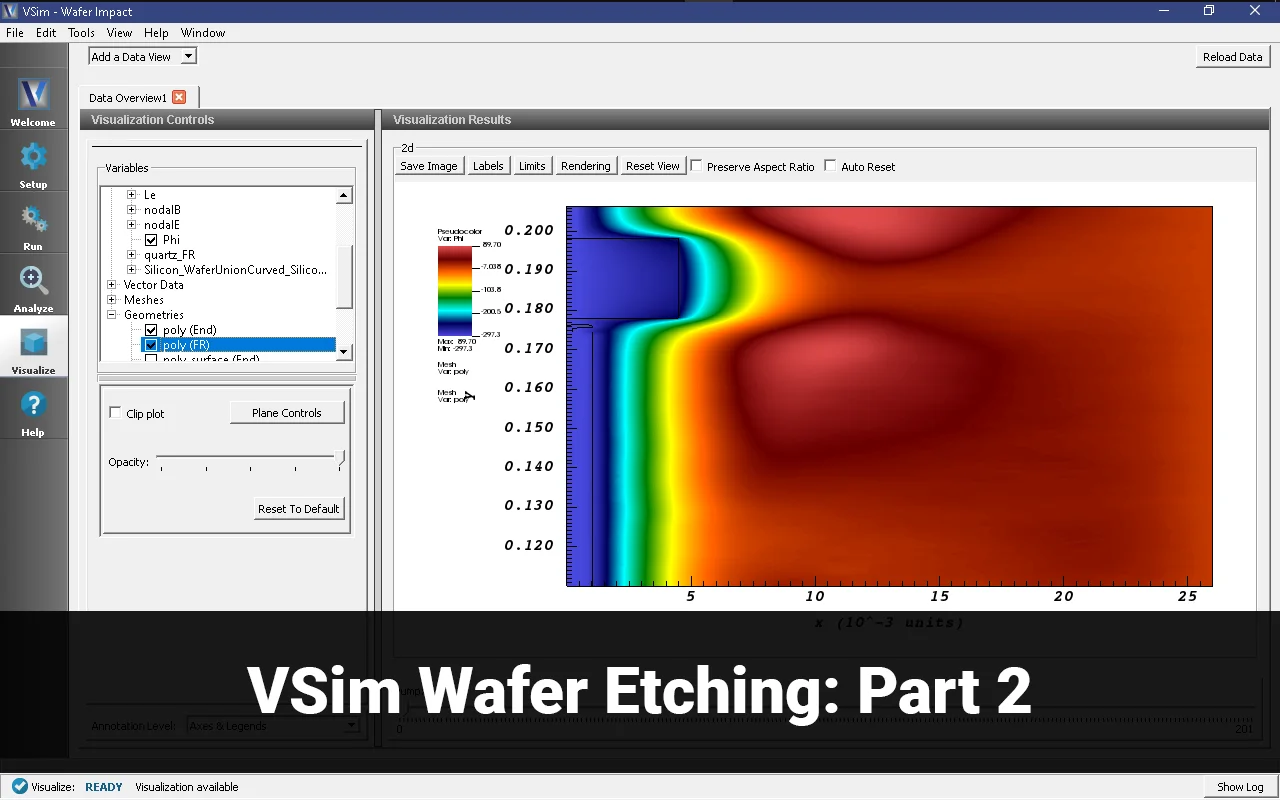

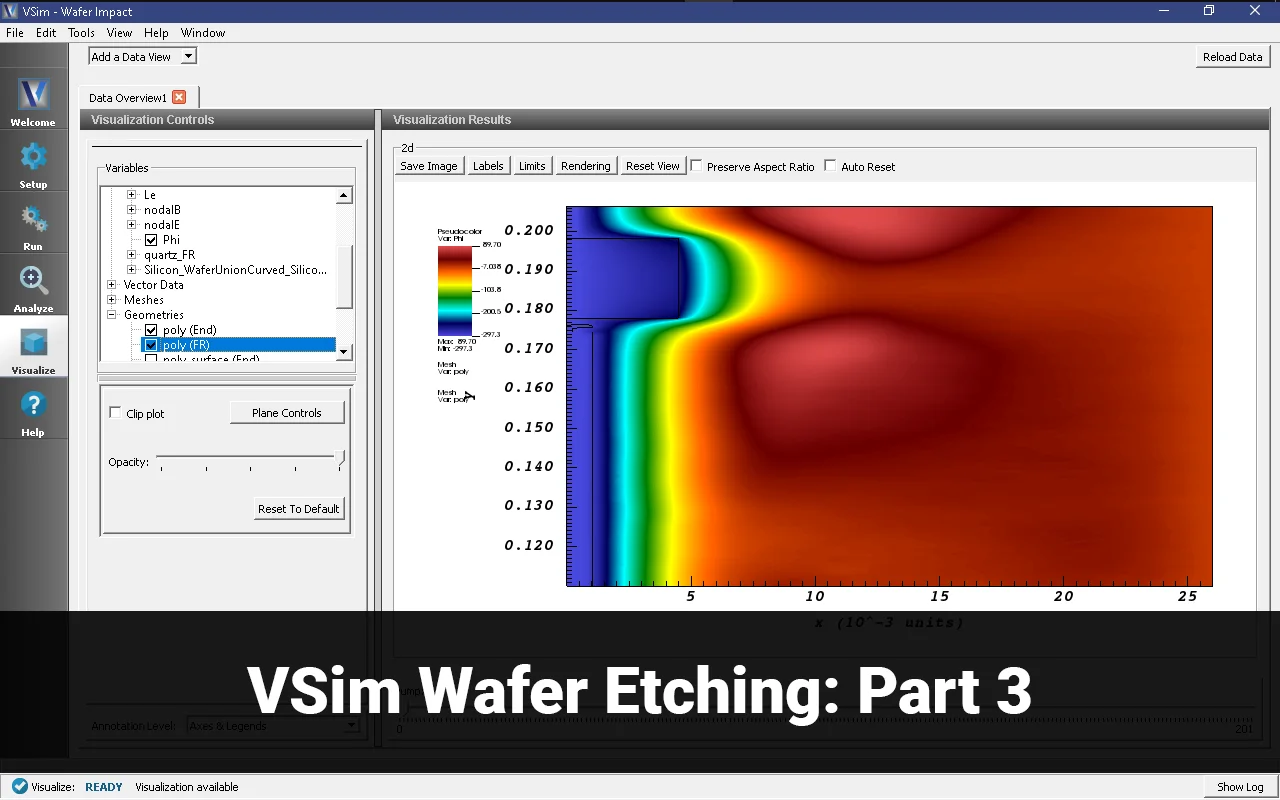

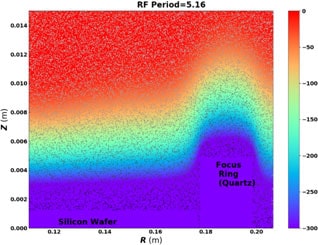

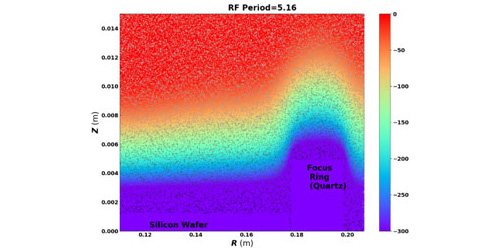

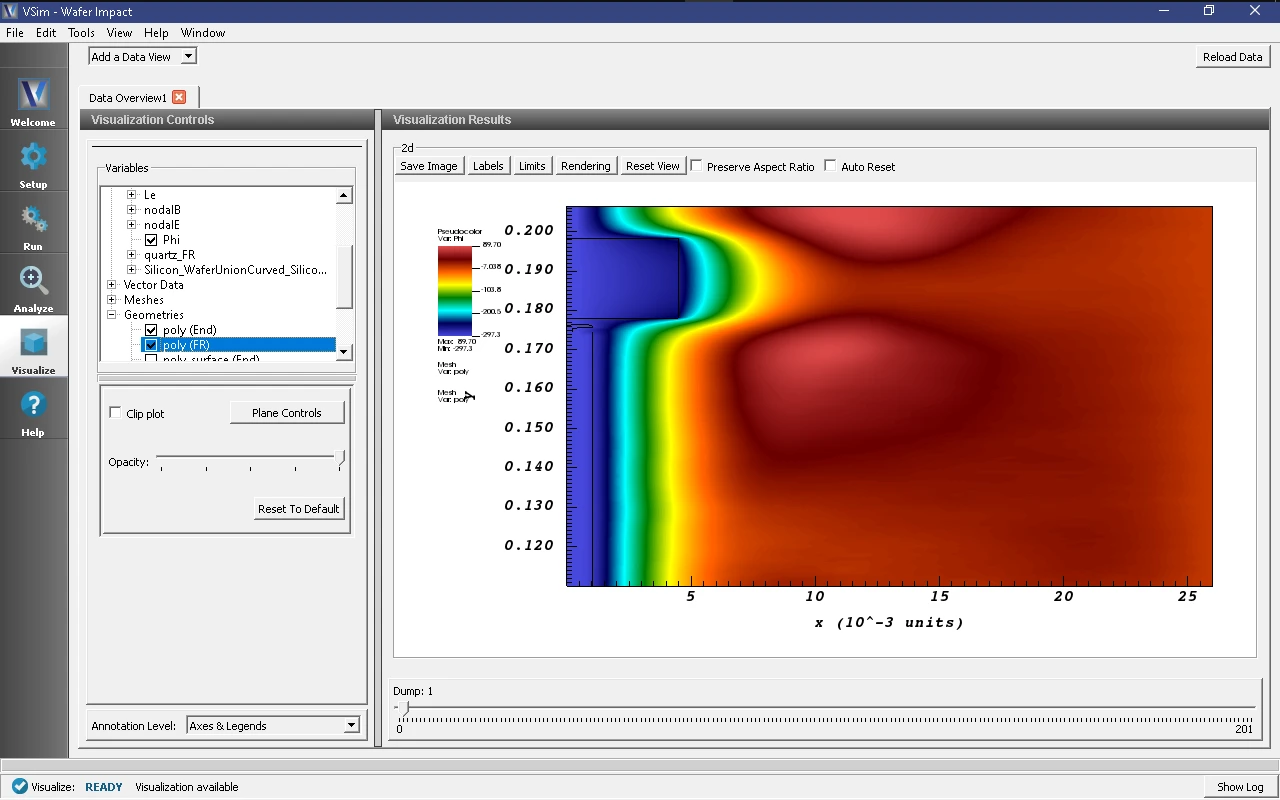

Using VSim, you can kinetically model all plasma species to correctly calculate the electric field at each time step. This is essential to correctly compute the sheath electric field, which directly affects the ion’s impact energy and angle. You can use VSim’s intuitive interface to create and visualize the wafer and surrounding dielectrics, which help create a more uniform wafer.

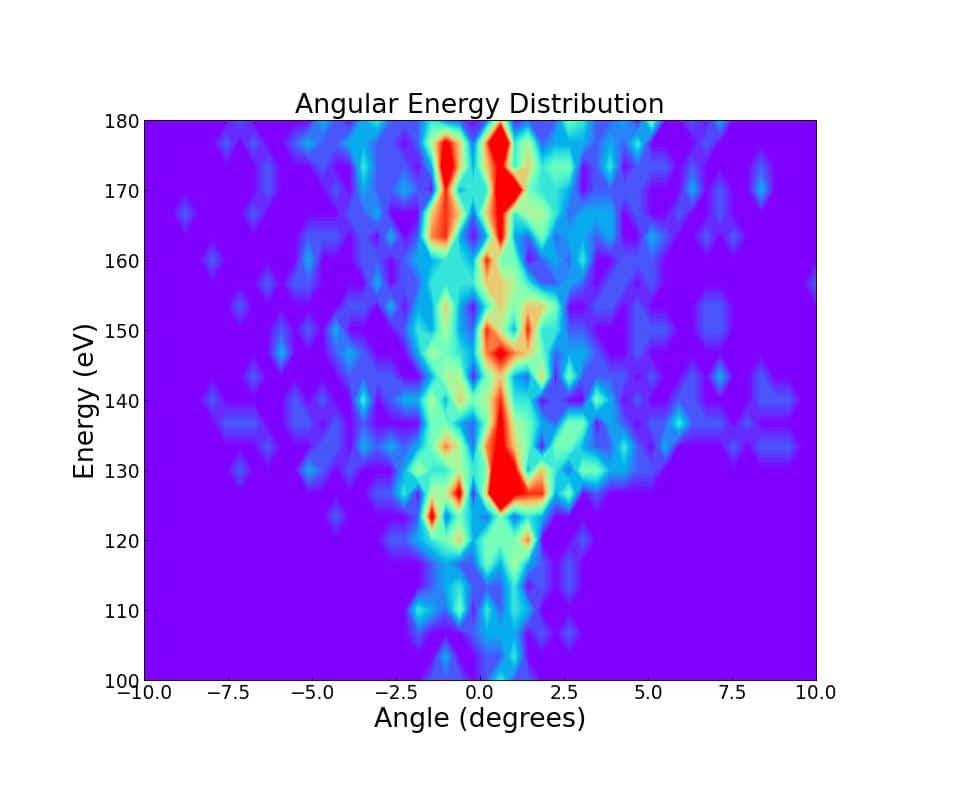

Simulate angle-energy distribution

Once the simulation is finished, you can compute the angle-energy distribution functions using our custom analyzer called computeAED.py. This analyzer bins the data from any kinetic species (ions or electrons) in energy and angle along any surface, such as the wafer. You can also bin in time according to your chosen time interval.